Restoration

of my 36HP Rumely #6153

By Jerred Ruble

Disassembly

|

Date |

Picture/Caption |

|

11/20/2010 |

|

|

11/20/2010 |

Nicholas

Swanz discovering why the engine would not turn all the way over - some

critters had set up housekeeping inside both cylinders. |

|

11/21/2010 |

Collin

removing some of the engine mounting bolts. |

|

11/21/2010 |

Although

we got excellent reading on the flue sheets and firebox, we needed to remove

the jacketing and get thickness reading of the barrel to ensure of the

overall condition of the boiler. Here |

|

11/21/2010 |

It

wasnít long and the engine proper was separated from the rest of the engine.

Here I am guiding the engine proper down to blocking sitting beside the rest

of the engine. |

|

11/21/2010 |

Here

the engine proper sets beside the rest of the engine on wooden blocking. |

|

11/25/10 |

When

we took a closer look at the engine proper we could see that the valve stem

was broken in two. After removing the steam chest cover we discovered that

the slide valve was broken into two pieces as well. It was obvious that

something bad had happened that took the engine out of service. Based on the

ware on the gearing and engine components though, the owners got their moneys worth before the catastrophic event occurred. |

|

11/27/2010 |

After

Lawrence made the modifications necessary to support the engine proper, we

moved the engine from the blocking we had set it on a week earlier to the

newly modified cart.. Here Collin and his grandfather Bob Hall guide the

engine unto the modified cart. |

|

11/27/2010 |

Here

the engine proper is mounted on its cart and on my trailer ready for

transport to |

|

11/27/2010 |

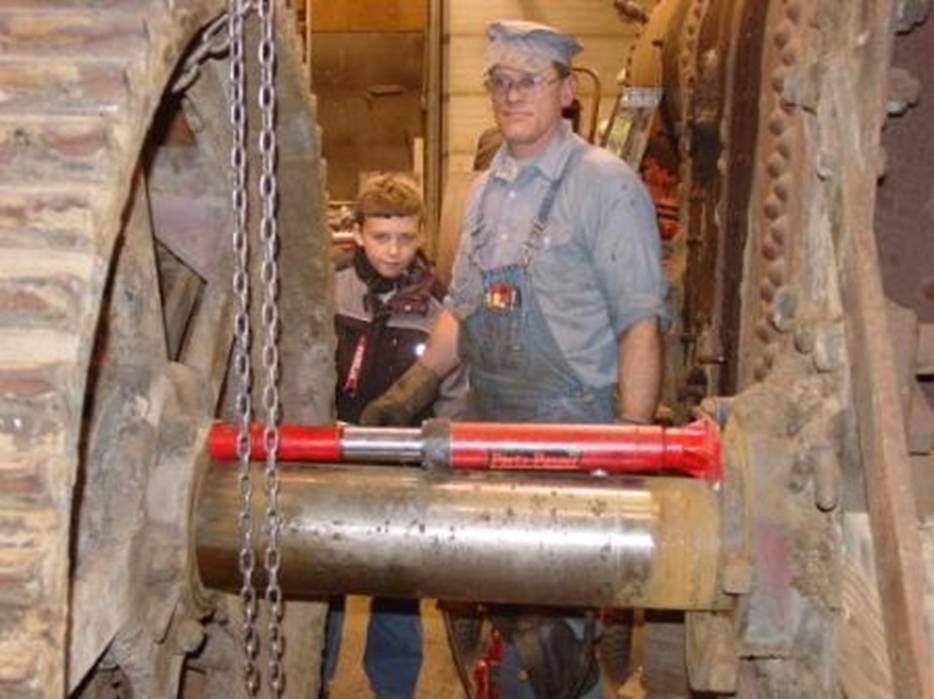

We

next turned our attention to removal of the gearing. Here Nicholas is using a

Porta Power to pull the right driver out so we

could get the differential gear and shaft out. We had a difficult time getting

the hubs removed from the driver axle. We had to torch the locking pins down

so the hub would come off. This required lots of heat, pounding, and

penetrating oil to accomplish. It took us several hours per hub. |

|

11/28/2010 |

Once

both drivers were out past the differential gearing we were able to remove

it. |

|

11/28/2010 |

Surprisingly,

the differential came apart very nicely thanks to the locking cap threads

being stripped. |

|

11/28/2010 |

Removal

of the intermediate gear and countershaft quickly followed. |

|

11/28/2010 |

Next,

we went to removing the left rear driver so we could remove the bull gear.

Here Lawrence and Nicholas are pushing the driver out with the aid of a Porta Power. |

|

11/28/2010 |

After

the bull gear was removed, we noticed one of the spokes in the gear was

broken clear through. From this and the overall condition of the gearing, it

was obvious that the old girl had been doing some serious pulling in her day. |

|

11/28/2010 |

We

put the naked driver back on the engine and moved the bull gear along side for safekeeping. |

|

11/28/2010 |

|

|

11/28/2010 |

The

above pictures show the state of the project after a couple of weekends of

work. I wish assembly would go as fast. |

|

1/23/2011 |

Lawrence, Eric Bremer and Brad Vinkenmeier disassembling

one of the front wheels. One of the hubs was broken and the other badly worn

so we decided to have then both re-furbished, |

|

2/12/2012 |

Collin and Cory cleaning bull gears getting them ready to take

to the foundry to have new ones made. |

|

5/13/2012 |

Nicholas and Lawrence removing the lower cannon bearing

with rear axle. |

|

7/11/2012 |

Collin and Nicholas disassembling the rear platform. |